Elektrik Gücü Kaynağı 55kw besleme motoru ile plastik konteyner imalatı için uygundur

| Durum | yeni | besleme motoru | 5.5KW |

|---|---|---|---|

| hoper malzeme | Paslanmaz çelik | Güç kaynağı | Elektrik |

| Ekstrüder motoru | 90/90kW | Kalıp Plakası Boyutu | 1500*1600 |

| Ortalama tüketim | 280kw | Kapasite | 220 litre |

| Vurgulamak | 55kw elektrikli davul üfleme kalıplama makinesi,Plastik konteyner üretme makinesi,besleme motoru patlama kalıplama makinesi |

||

![]()

Ürün Tanımı:

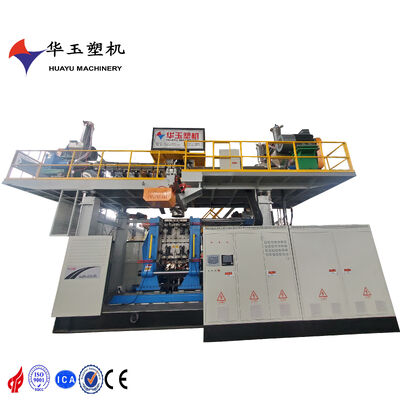

Davul Üfleme Kalıplama Makinesi, plastik davul ve kapların üretimi için özel olarak tasarlanmış yüksek verimli ve dayanıklı bir ekipmandır.Endüstriyel üretimin katı taleplerini karşılamak için tasarlanmıştır., bu patlama kalıplama makinesi, sabit performans ve uzun ömürlü güvenilirliği sağlamak için ileri teknolojiyi sağlam yapıyla birleştirir. 1500*1600 kalıp plaka boyutuyla,Büyük boyutlu davulları hassasiyet ve tekdüzelikle üretebilir., plastik tambur üretim faaliyetlerini genişletmek isteyen işletmeler için ideal bir seçim haline getirir.

Bu fırça makinelerinin öne çıkan özelliklerinden biri olağanüstü dayanıklılığıdır.Sürekli çalışma koşullarında bile uzun bir hizmet ömrü garanti eder.Bu dayanıklılık, düşük duraklama süresi ve bakım maliyetleri ile sonuçlanır ve nihayetinde genel üretkenliği artırır.Makinenin dayanıklılığı, büyük hacimli üretim ortamlarının gerginliklerine dayanabilmesini sağlar, kaliteyi tehlikeye atmadan tutarlı bir çıkış sağlar.

Makine, sadece dayanıklılığını artırmakla kalmayıp aynı zamanda hijyenik işleme koşullarını da sağlayan paslanmaz çelikten yapılmış bir hopper ile donatılmıştır.Paslanmaz çelik hopper korozyona dayanıklı ve temizlenmesi kolayBu malzeme seçimi hammaddelerin saflığını korumaya yardımcı olur ve kontaminasyonu önler.endüstri standartlarına uygun yüksek kaliteli plastik kaplar üretmek için çok önemlidir..

Bir elektrik kaynağı tarafından çalıştırılan bu alçaltma makinesi, enerji tasarruflu çalışmayı ve üretim süreci üzerinde hassas bir kontrolü sağlar.Elektrikli güç sistemi, tüm makine bileşenlerinin sorunsuz ve güvenilir çalışmasını sağlar, tutarlı döngü sürelerini ve en iyi enerji tüketimini sağlar.Bu özellik, yüksek üretim oranlarını korurken işletme maliyetlerini en aza indirmek isteyen üreticiler için özellikle faydalıdır.Elektrik güç kaynağı ayrıca otomatik sistemlerle kolay bir entegrasyonu destekler, bu da gelişmiş süreç kontrolünü ve daha az işgücü gereksinimini sağlar.

Özellikle plastik davul ve kaplar üretimi için tasarlanan bu darbe kalıplama makinesi, katı kalite ve performans kriterlerini karşılayan ürünler sunmada öne çıkıyor.Gelişmiş darbe kalıplama teknolojisi, duvar kalınlığını eşit kılar., minimum malzeme israfı ve üretilen tamburların mükemmel yüzey finişi.çeşitli endüstriyel uygulamalarda dayanıklılığı ve dayanıklılığı ile bilinen popüler bir tasarımBu darbe kalıplama makinesini kullanarak, üreticiler üstün darbe direnci ve yapısal bütünlüğü sunan çift l halka davulları üretebilirler.

Drum Blow Moulding Machine sadece bir ekipman parçası değil; plastik tambur üretim süreçlerini optimize etmek isteyen üreticiler için kapsamlı bir çözümdür.Büyük bir kalıp plaka boyutunun kombinasyonu, yüksek dayanıklılık, paslanmaz çelik hopper ve elektrik güç kaynağı, geniş bir plastik kaplama üretimi için çok yönlü ve güvenilir bir seçim haline getirir.Kimyasal depolama için fıçılar üretip üretmediğiniz, gıda işleme veya endüstriyel kullanım, bu makine tutarlı kalite ve verimlilik sağlar.

Özetle, bu darbe kalıplama makinesi plastik tambur üretimi için sağlam ve verimli bir araç olarak öne çıkıyor.Büyük kalıp plaka boyutu 1500 * 1600 büyük konteynerlerin üretimi için izin verir, yüksek dayanıklılığı uzun süreli operasyon güvenilirliğini sağlarken paslanmaz çelik hopper malzeme işleme hijyeni artırır,ve elektrik güç kaynağı enerji verimli ve hassas bir çalışma sağlarÇifte l halka davulları ve diğer plastik kaplar üretimi için idealdir, bu patlama kalıplama makinesi kaliteye, verimliliğe odaklanan herhangi bir plastik üretim tesisi için vazgeçilmez bir varlıktır.ve ölçeklenebilirliği.

Özellikleri:

- Ürün Adı: Davul Üfleme Kalıplama Makinesi

- Ortalama güç tüketimi: 280KW

- vida çapı: 110/110mm

- Güç Kaynağı: Elektrik

- Kalıp plaka boyutu: 1500*1600 mm

- Kapasite: 220 litre

- Büyük ölçekli üretim için uygun yüksek verimlilikli davul üfleme kalıplama makinesi

- Sürekli performans için tasarlanmış dayanıklı darbe kalıplama makinesi

- Gelişmiş üfleme kalıplama makinesi teknolojisi, hassas ve güvenilir kalıplama sağlar

Uygulamalar:

Huayu HYBM-220 davul üfleme kalıplama makinesi, plastik davul ve kapların üretimi için tasarlanmış gelişmiş ve güvenilir bir çözümdür.Bu son teknoloji üfleme kalıplama makinesi yüksek kaliteli ihtiyaç duyan endüstriler için idealdir, dayanıklı ve verimli tambur üretimi, özellikle L halka tamburları.HYBM-220, optimal performans seviyelerini korurken enerji verimli çalışmayı sağlar.

Çeşitli plastik tambur ve kaplar üretmek isteyen üreticiler, Huayu HYBM-220 tambur üfleme kalıplama makinesini üretim hatları için mükemmel bir şekilde uygun bulacaklardır.ve SGS sertifikaları uluslararası kalite ve güvenlik standartlarına uygunluğu garanti eder, hem yerli hem de uluslararası pazarlar için güvenilir bir seçim haline getirir.Modern imalatın zorlu gereksinimlerini karşılamak için hassasiyet ve gelişmiş teknolojiyle üretilmiştir..

Davul üfleme kalıplama makinesinin çok yönlülüğü, birçok uygulama senaryosunda kullanılmasına izin verir.gıda işlemeÖzel ambalajlama çözümleri gerektiren şirketler, makinenin müşteri ihtiyaçlarına göre çeşitli ambalajlama detaylarını barındırma yeteneğini takdir edeceklerdir.Üretimde esneklik ve uyarlanabilirlik sağlamak.

Yeni durumu ve sağlam tasarımı nedeniyle, HYBM-220 sürekli, yüksek hacimli üretim için uygundur.Yıllık 40 set tedarik kapasitesi, üreticilerin operasyonlarını verimli bir şekilde ölçeklendirmelerini sağlarMinimum sipariş miktarı sadece bir set ile, işletmeler TT veya L / C gibi esnek ödeme şartları ile desteklenen bu darbe kalıplama makinesine güvenle yatırım yapabilirler.

4-5 aylık teslim süresi, müşterilerin davul üfleme makinelerini makul bir zaman diliminde almalarını sağlar, böylece üretim programlarını etkili bir şekilde planlamalarını sağlar.Fiyatlar müzakere edilebilir., Huayu'nun müşteri gereksinimlerine göre tasarlanmış maliyetli çözümler sunma taahhüdünü yansıtıyor.

Özetle, Huayu HYBM-220 davul patlama kalıplama makinesi, plastik davul ve kaplama üretimiyle uğraşan şirketler için mükemmel bir seçimdir.Enerji verimli elektrik enerjisi ve sertifikalı kalite ile birleştirilmişBu makine, endüstriyel veya ticari uygulamalar için olsun, güvenilir, esnek ve yüksek kaliteli davul üretimini destekler.

Özellik:

Huayu Drum Blow Moulding Makinemiz, HYBM-220 modeli, çeşitli üretim ihtiyaçlarını karşılamak için tasarlanmış yüksek kaliteli bir hdpe davul makinesi.Bu plastik davul makinesi güvenilir performans ve uluslararası standartlara uygunluğu sağlar.

90/90kw'lık güçlü bir ekstrüder motoruna ve ortalama 200kw'lık bir güç tüketimine sahip olan HYBM-220, uzun ömürlü Double L halka davullarını hassasiyetle verimli bir şekilde üretir..5kw, ve hopper uzun süreli çalışma ve malzeme güvenliğini garanti etmek için paslanmaz çelikten yapılmıştır.

Özel gereksinimlerinize göre esnek ürün özelleştirme hizmetleri sunuyoruz. En az sipariş miktarı sadece bir set ve fiyatlandırma bütçenize uygun olarak müzakere edilebilir.Paketleme detayları müşteri ihtiyaçlarına göre uyarlanabilir., güvenli ve uygun teslimatı sağlar.

Huayu hdpe davul makinesi için teslimat süresi tipik olarak 4-5 aydır ve TT veya L / C yoluyla ödeme şartlarını destekleriz.Plastik davul makinesi yatırımınız için tutarlı kullanılabilirlik ve mükemmel satış sonrası destek sunmaya kararlıyız.

Destek ve Hizmetler:

Bizim Drum Blow Moulding Makinemiz plastik davulların üretiminde yüksek verimlilik ve hassasiyet sağlamak için tasarlanmıştır.Kapsamlı teknik destek ve hizmetler sunuyoruz..

Teknik Destek, kurulum, işletme ve bakım prosedürleri hakkında uzman rehberlik içerir.ve gelişen üretim ihtiyaçlarını karşılamak için ekipmanlarınızı yükseltmek.

Beklenmedik duraklamaların önlenmesine ve makinenizin ömrünü uzatmasına yardımcı olmak için planlı bakım hizmetleri sunuyoruz.ve yazılım güncellemeleri.

Operatörleriniz ve bakım personeliniz için eğitim programları mevcuttur.Kişiselleştirilmiş eğitim seansları tesisinizde veya uzaktan düzenlenebilir.

Ek olarak, kritik bileşenlerin mevcutluğunu garanti etmek ve üretim kesintilerini en aza indirmek için yedek parça tedarikleri sunuyoruz.Yedek parçalarımız uyumluluğu ve dayanıklılığı sağlamak için en yüksek standartlara göre üretilir..

Herhangi bir teknik sorgu veya servis talebi için, lütfen ürün belgelerinize bakarak destek ekibimizle iletişime geçmek için uygun prosedürleri öğrenin.